The Challenge:

One manufacturer, who provides consumer product machines for a leading food and drink company, had been asked to remove all non-recyclable elements within the product including the packaging. This wasn’t a problem for the product, however the packaging had high levels of polystyrene and plastic bagging. Our client needed an alternative that was recyclable and would keep their products safe during transportation. They came to Sandland.

The Solution:

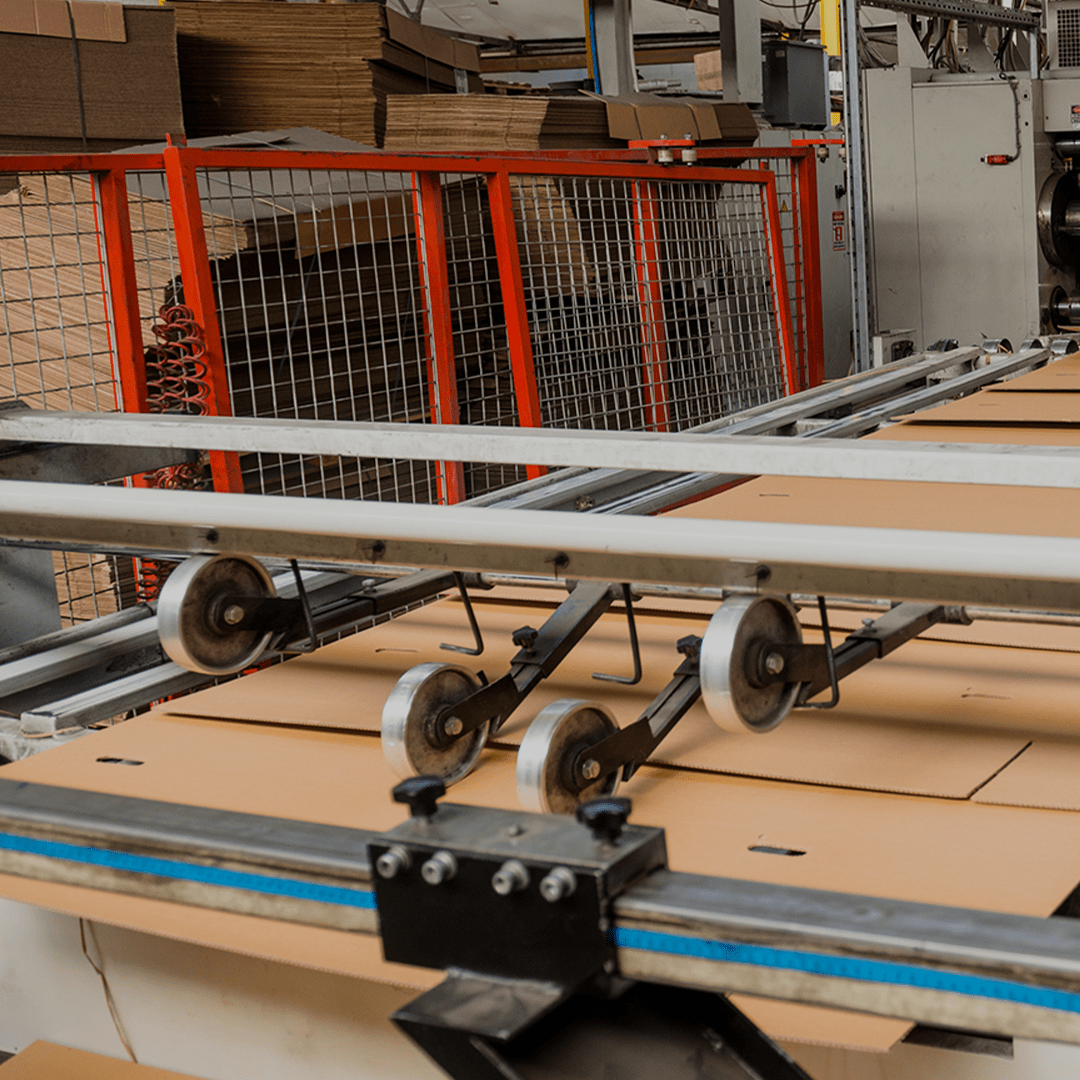

To ensure complete protection we replicated the polystyrene with cushion pack style die-cut fitments made from corrugated cardboard. These allowed the product to be drop tested with similar protective levels to the polystyrene but this time with a cushion effect – allowing the packaging to crumple to a safe level protecting the product.

The Result:

Once all the designs were finalised we achieved what we set out to do. The entire outer and inner protective packaging was now 100% recyclable and produced from recycled material.

Related Projects

Let us help you