Introduction

VR ProOptics are a leading provider of virtual reality prescription lenses. The team had been using the same packaging for some time and had taken the decision to make some improvements.

Stephen Brazell, Ophthalmic Production Consultant Engineer, confirms, “We understand the importance of packaging and a re-design provided an opportunity for us to have a better presentation experience for our customers. These are high value items and we wanted to impress customers, emphasise our quality and increase our sustainability criteria.”

The Challenge:

Stephen and the team had specific concerns they wanted to address, “We were putting our lenses into a small square box which then went into a mailing bag, so not only were we double handling, the outer mailing bag had no branding, and once the customer had received it, the whole lot went into the bin – this was something we wanted to change.”

The presentation of the product was also important, “A great unboxing experience adds a quality feel and it’s important to us where we place ourselves in the market. It’s a simple way to show your customers that you care about how you present their purchase.”

Key requirements from VR ProOptics:

- Single piece die-cut box

- Efficient and cost effective to use

- Branded packaging

- Enhanced customer unboxing experience

- Environmentally responsible

- Recyclable

Introduction

An automotive manufacturer needed a packaging solution that would protect delicate rear door panels. Their current system was inefficient, prone to damage, and not scalable for increasing production volumes.

The Challenge:

Key requirements included:

- Precise, protective fit for each unique component.

- Easy identification and access during assembly.

- Scalable for volume production and repeatability.

- Sustainable and cost-effective material use.

The Solution:

Ethan from design agency, New Rhythm Design did some research and thought the case studies on the Sandland Packaging website showed the capability for creating clever unique die-cut printed boxes were the type needed.

Stephen continues, “Ethan approached Sandland Packaging and Kieron responded really quickly. Ethan was able to explain our requirements and send a prototype box that he had put together. Kieron was great in explaining the options and was able to improve on the initial concept design and refine it so that it was both visually better and more cost effective to manufacture. He guided us through the entire process to final order, which included implementing the branded artwork design from New Rhythm Design.”

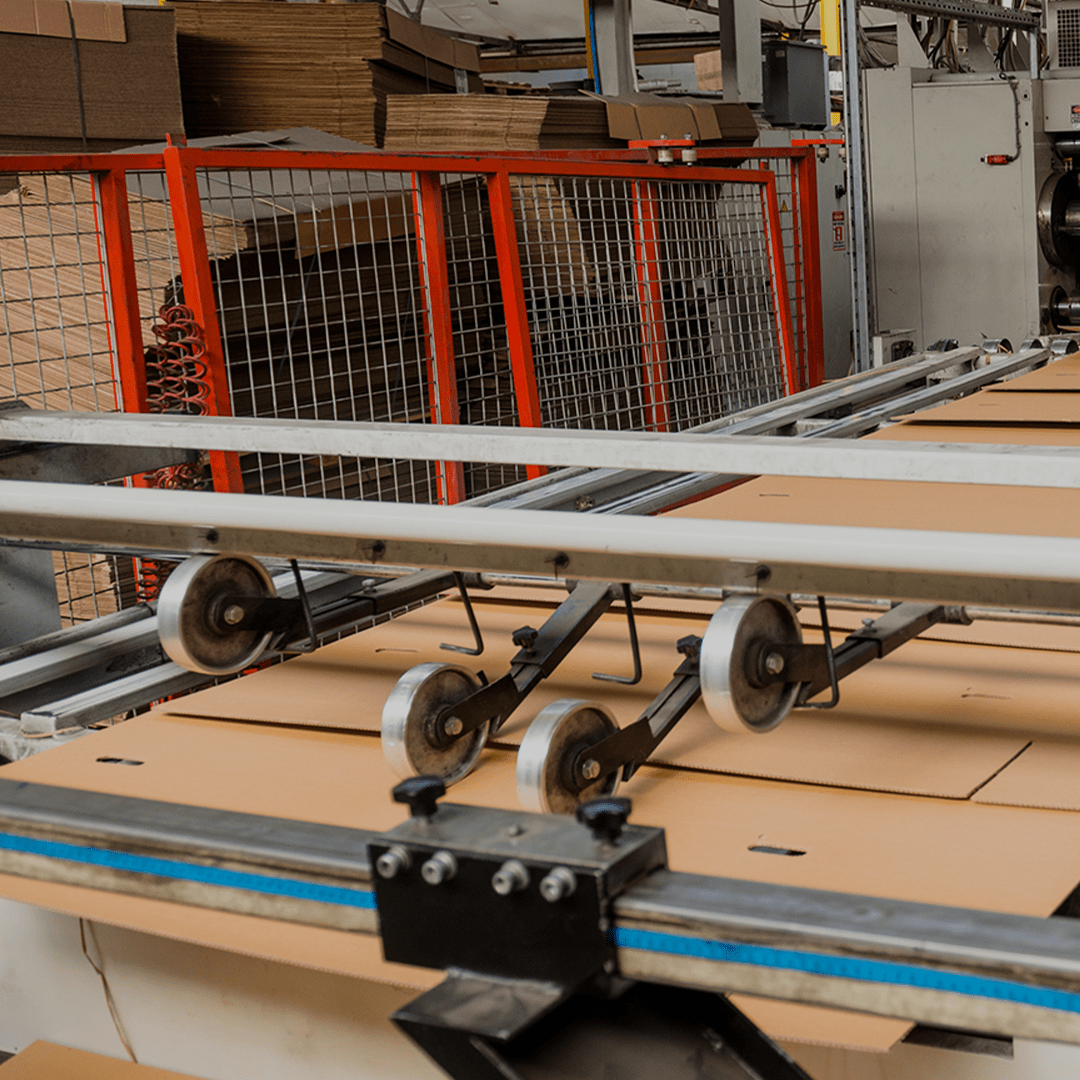

To meet the specification, we designed a bespoke corrugated box tailored to fit both lenses and glasses cases, through including a simple perforation which changes the aperture in the box if it is required to hold glasses cases instead. The boxes close tightly to hold the items securely for transportation and delivery.

A striking single colour print on the outside of the box was used. Stephen continues, “It was great to be able to print on the box – it helped enhance the brand and build engagement with our customers. It was also really important for us to let the customer know that the product and the packaging were all made in the UK. Lastly, for security, we wanted to make it clear to anyone handling the product that the lenses were all prescription – so personalised to the person placing the order.”

Our solution included:

- Single piece box with die-cut aperture to snugly hold the product

- Perforated area to change to hold glasses cases

- Attractive single colour printing for brand engagement

- Lightweight, fully recyclable corrugated material

The Solution:

Sandland Packaging designed a bespoke corrugated fitment system tailored to fit as many doors as possible. The custom interior packaging kept items secure, separated, and properly supported within the outer box, reducing movement and eliminating the need for plastic inserts.

Our solution included:

- Custom die-cut cardboard fitments for every components

- Layered inserts to separate and protect individual parts

- Lightweight, fully recyclable and carbon neutral corrugated material

The Result:

Stephen is thrilled with the new boxes, which he feels are a real improvement. “Ethan and Kieron worked together to deliver a fantastic result for us. We love our boxes! We’re so pleased we chose Sandland Packaging to create the boxes that New Rhythm Design conceived. The boxes meet all of our criteria – impressive, robust, modern, sustainable – they are everything and more we were looking for.”

- Brand building, striking print

- Simple, one-piece construction.

- Fully recyclable and Carbon Neutral

- Flexible packaging design for multiple use

The Result:

The customer saw a marked improvement in both handling efficiency and part protection. Damage during transit was reduced, assembly teams experienced quicker part retrieval, and the packaging aligned with the company’s sustainability targets.

- Zero component damage reported after rollout.

- Faster assembly line processes thanks to better organisation.

- Fully recyclable Carbon Neutral Material meaning our customer can mark their packaging as ZERO emissions on the GHG Scale.

- Scalable packaging design for future production growth.

Related Projects

Let us help you